Sample Career Episodes On Chemistry

Download - 1 | Published :25th June 2015

Career Episode 1

Introduction

CE 1.1

This career episode 1 will provide a concentrated snapshot of the project “Manufacture of Polymer Grade lactic Acid”. I have completed this project as a student of Sinhgad College of engineering. This college is established under the affiliation of the Pune University. I have completed this project on May 2009 as a part of my chemical engineering course work.

Chronology: May 2009

Physical Location: Pune, India

Name of the Organization: Sinhgad College of Engineering, Sinhgad Technical Education Society

Position held: Student

Name of the Project: Manufacture of Polymer Grade Lactic Acid

Background

CE 1.2

In 1780, the Swedish chemist Scheele discovered the existence of the lactic acid. However,Charles E. Avery in Massachusetts, USA, produced it for the first time. Lactic acid is the widely producing carboxylic acid within the normal natural condition. Lactic acid is the simplest form of the hydroxyl acid. This acid contains one carbon atom that is asymmetric in nature.

The naming convention of this acid has been influenced by milk. The main reason for this is that it was initially found in the milk. However, the scientific name of this acid is 2- hydroxpropanoic acid [16]. The compounds that can be derived from the lactic acid are substituted propionic acid materials.

CE 1.2.1

The Physical Properties of the lactic acid

During the course of the project, I have found many physical properties of the Lactic Acid. The physical properties what I have found during the project has been illustrated through the following tabulated format for the better understanding.

|

Property of the Lactic Acid |

Value |

|

Chemical Formula |

C3H6O3 |

|

Chemical Abstracts Registration |

CAS.-Reg.-No. [79-33-4] |

|

Molecular Weight |

90.08 |

|

Taste |

Mild Acidic |

|

Physical Appearance |

Aqueous Solution |

|

Melting Point |

530 C/ 127 0 F |

|

Boling Point |

2000 C / 3900 F |

|

Solubility in water(g/100 g H2O) |

Miscible |

|

Dissociation Constant, Ka |

1.38 * 10^ -4 |

|

pKa |

3.86 |

|

pH (0.1 N solution, 25oC) |

2.4 |

|

pH (0.1% solution, 25oC) |

2.9 |

|

Odor |

Slight acrid odor |

|

Specific Gravity |

1.2 |

|

Stability |

Quite stable under ordinary conditions of use and storage |

CE 1.2.2

Chemical Properties

Oxidation of the lactic acid provides the formation of the formic acid and the oxalic acid. The chemical reaction that completes the oxidation is :

5CH3CHOHCOOH + 4MnO4 - + 12H+ à 5CH3COOH + 5CO2 + 4Mn2 + 11H2O

The cerium reaction for the lactic acid is one of the most complicated. The reaction is:

CH3 CHOHCOOH +CeIV ß àCH CHOHCOOCeIV ® CH CHOH- +CO2 +CeIII

The oxidation process can be completed using chromic acid. The oxidation process through using the chromic acid is as follows

CH3 CHOHCOOH + H2 CrO4 ß à CH3CHOCOOHCrO3 H ®CH3 COCOOH + H2 CrO3

CE 1.2.3

Corrosion

The manufacturing of the lactic acid is not so easy. It develops many technical issues even in the case of handling. To handle the corrosion while manufacturing the lactic acid four groups of metals can be used. These four groups of metals can be classified into following way according to the metal’s resistance to corrosion by lactic acid.

The groupings of the metals are as follows:

- Purely non noble metals that is soluble in the lactic acid through the evaluation of the hydrogen. Through I have found that there are some mental that develops a type of protective coating or corrosion products.

- Metals that creates reaction with the lactic acid in the presence of the oxygen. However, here I have found that the corrosion rate is completely depends on the rate oxygen reaches the surface of the metal.

- Passive metals, the nature of this metal is that it can initiate and perform the corrosion in the presence of the air. I found that the nature of passivity develops due to the presence or the formation of the protective layer. Due to this nature, the acid can be break up in passive formation.

- Metals that are not corroded by the lactic acid.

CE 1.2.4

Optical Activity

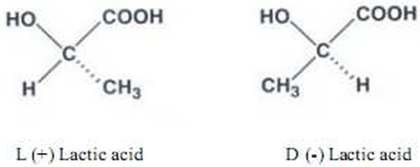

The optical nature of the compound is said to be optically active when it can rotates the plane of the polarized light. The formula that can given the optical activity is 2n2 . In this formula the n denotes the total number of asymmetric carbon atoms present within the compound.

I found that the Lactic acid contains only one asymmetric carbon atom. Therefore, according to the formula cited in the first paragraphs I found that the optical activity of lactic acid is 2. The following figure will illustrate the optical activity of the lactic acid.

CE 1.3

Use of the Lactic Acid

This acid is one of the most widely used acids in the daily life. I found that this acid is most widely used in vegetables as an acidilant and in leather industry to tan the leather. However, the textile and the food industry have used the lower grade lactic acid with the inorganic acid. Other than these, the lactic acid has been used in the many small-scale areas to maintain the pH balance of the materials like cellophanes hardening baths, solder flux, electropolishing and electroplating baths. Other than these sectors, the detergent manufacturing companies use this acid very frequently.

I found wide use of this acid has been used widely in the cosmetics and the pharmaceutical industries. It has been used in the development of the lotions, ointments that are topical in nature, anti acne solutions and in the dialysis applications. This acid in the form of calcium lactate has been used to treat the calcium deficiency in the human body. I found that this acid has been used by the polymer industries to develop the biodegradable thermoplastic. I found that the byproduct of the lactic acid methyl lactate is also used very highly by the pharmaceutical industries. The medical professionals to treat different diseases have used the purest quality lactic acid.

CE 1.4

Manufacturing through the Chemical Synthesis

The lactic acid can be manufactured through two processes. Among them, the most popular is the manufacturing through the chemical synthesis. The commercial sector runs the chemical synthesis based on lactonitrile. The chemical reaction happens in the liquid pressure at higher atmospheric pressures.

The process of the chemical reaction follows the following sequential reactions.

- Hydrogen Cyanide addition:

CH3CHO + HCH –catalystà CH3CHOHCN

In this reaction, the acetaldehyde through the reaction with the hydrogen cyanide in the presence of the proper catalyst develops the lactonitrile.

- Hydrolysis through H2SO4

CH3CHOHCH + H2O + ½ H2SO4 -à CH3CHOHCOOH + ½ (NH4)2SO4

In this chemical reaction, the lactonitrile reacting with the sulphuric acid develops the lactic acid and as a byproduct of this chemical reaction ammonium salt develops.

- The Esterification

CH3CHOHCOOH + CH3OH -à CH3CHOHCOOCH3 + H2O

In this chemical reaction, the lactic acid reacting with the methanol develops the methyl lactate and as a byproduct, it develops water.

- H2O Hydrolysis

CH3CHOHCOOCH3 + H2O -à CH3CHOHCOOH + CH3OH

In this reaction, the methyl lactate reacting with the water develops the lactic acid and the methanol.

While studying on the manufacturing of the lactic acid through chemical synthesis I found that the only two companies are using this method to produce the lactic acid. Those two companies are Sterling Chemicals Inc. of United States Of America and the Musashino of Japan.

However, I found that there is another way to manufacture lactic acid. This is through the catalyzed degradation of sugar, reaction of acetaldehyde, oxidation of propylene glycol, water and carbon monoxide.

CE 1.5

Manufacturing of Lactic Acid through Carbohydrate Fermentation

The manufacturing of the lactic acid can be done through the carbohydrate fermentation. The manufacturing of the lactic acid depends on the strain used while the chemical reaction has ben conducted.

I found that the manufacturing of the lactic acid through the carbohydrate fermentation follows the following steps.

- Neutralization and Fermentation

C6H12O6 + Ca (OH)2 ----fermentationà 2(CH3CHOHCOO)Ca2+ + 2H2O

In this reaction, the carbohydrate through the calcium hydroxide develops the calcium lactate and water as the byproduct.

- Hydrolysis through H2SO4

2(CH3CHOHCOO)Ca2+ + H2SO4 -à 2CH3CHOHCOOH + CaSO4

In this reaction, the calcium lactate through the hydrolysis with the H2SO4 develops the lactic acid and the calcium sulphate as a byproduct of the hydrolysis.

- The Esterrification

CH3CHOHCOOH + CH3OH à CH3CHOHCOOCH3 + H2O

In this reaction the lactic acid through the esterification produces the menthol and the methyl lactate.

- Hydrolysis through H2O

CH3CHOHCOOCH3 + H2O à CH3CHOHCOOH + CH3OH

In this hydrolysis through the water the methyl lactate turns in to the lactic acid and as a byproduct of this hydrolysis methanol comes out.

CE 1.6

Manufacturing process

While I was working on the project I found that, the commercial production processes follows a few very specific process. The production process follows the following steps

- Crude lactic acid preparation

- Esterification through trickle phase continuous counter current method

- Esterification through trickle phase continuous counter current method through hydroquinone stabilizer

- Esterification through trickle phase continuous counter current method through the doping of known impurities in the feed of lactic acid

- Highly pure methyl lactate isolation

- Highly pure S-(-)-methyl lactate hydrolysis to extract the highly pure L-(+)- lactic acid

CE 1.7

Reactors used for the manufacturing of the Lactic Acid

To produce the polymer grade lactic acid commercially I found that two types of fluid-fluid reactors were used. One is column or tower reactors and the other one is the tank reactors.

CE 1.8

Required Materials and Energy Balance

The following list will provide the list for the required material and the required energy balance.

- Required Output: 3500 TPA (Tons per annum) of 90 wt.% L(+) lactic acid.

- Plant Running: 24 hours for 300 days in a year.

- Module basis required output:111 mols/hr of L (+) Lactic Acid and 2700.617 mols/hr of water.

Summary

CE 1.9

Throughout this career episode, I have found the various aspects of the lactic acid usage and the production process of it. I found that the lactic acid can be produced in two ways and I have learnt both the ways. However, I found that while the production of the lactic acid goes into the commercialization the process and the complexity of the manufacturing becomes complex.

Career Episode 2

Introduction

CE 2.1

In this career episode, I have developed biodiesel using the algae as a source. I have done this project through taking the sole responsibility. I have done this project as a student of the Sinhgad College of Engineering. This college is established under the affiliation of the Pune University. This project was very much require to complete my course.

Chronology:

Physical Location: Pune, India

Name of the Organization: Sinhgad College of Engineering, Sinhgad Technical Education Society

Position held: Student

Name of the Project: Biodiesel from Algae

Background

CE 2.2

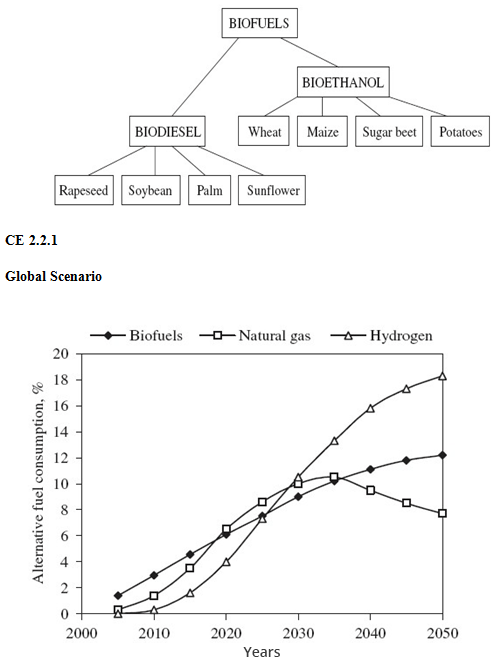

The growing trend of the global warming and the decreasing resource of the conventional energy have boosted the trend of the development of the alternative fuel. In the alternative fuel development, the biodiesel is leading the path.

I have found that in recent time the most of the renewable energy companies are trying to develop the sustainable biodiesel from the sugarcane and from the oil crops. The raw development procedure what I have found while working in this project is that the biodiesel is coming through the carbohydrates conversion within the plants.

The biodiesel family has been illustrated through the following figure.

I found that the most of the developed and the emerging nations are trying to promote the use and the production of the biodiesel to reduce the use of the conventional fuel. The countries like the USA are promoting the use of biodiesel very aggressively. The International energy agency and the European union have taken a initiative to increase the use of biodiesel in the commercial segment up to 6% within a five year period. The emerging economies like the India and China are promoting the research and development of the biodiesel to draw the trading advantage. Therefore, I have experienced that the future of biodiesel as a non-conventional fuel in the global market is very much bright.

CE 2.3

The advantage of the biodiesel

Biodiesel as a commercial product is having a very bright future. However, the other advantages for the development of the biodiesel are:

- The source of the biodiesel is in the CO2 combustion cycle

- The biodiesel can be obtained from the commonly available biomass very easily

- The sustainability of the biodiesel is very much higher than the other renewable resources

- The use and the development of the biodiesel are very much advantageous for the nation’s economy also. On this context I have seen that if the EU remains to reduce the spending by 6% in the conventional energy resources they will remain able to save a lots of spending and that will strengthen the EU’s economy.

CE 2.4

Microalgae biofuel

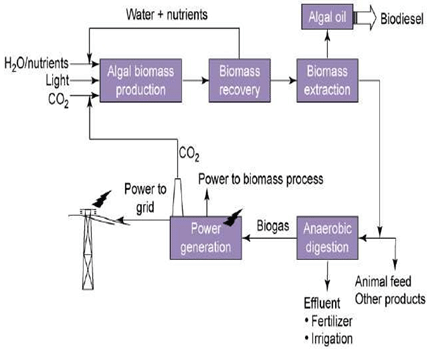

The photosynthetic microalgae are the special kind of microorganism that converts sunlight, carbon dioxide and water into the algal biomass. I have seen that these kind of algal are the source of rich oil. The oil resource from these algal can be a source of the commercial interest for the stakeholders of the biodiesel project in the future times. The entire development cycle of the energy through the microalgae has been illustrated through the figure.

The algal bio mass has been produced through the cultivation of the microalgae. During the bio mass production, the external nutrients have been added to increase the growth of the algal. Once the bio mass recovery is done then the bio mass has been extracted from the recovered biomass for the energy production. After this process through the animal feed and the other process the required resource has been obtained. Then from this resource, the bio energy has been developed through the biogas.

CE 2.5

Biomass algae properties

Algae is the most diverse atmospheric organism. The formation of the algae has been ranged from the unicellular to the multi-cellular. I have learnt that through the different journals and the books that in present time almost 30,000 different algae are present. Among this 30,000 different species 10,000 different resources are found within the marine water. However, I have learnt that the most effective algae are those algae that have the chloroplasts and membrane. The other thing, what I have found that the algae can be found in various different formats. The format ranges from the land plant to the sea plants. All the algae produce the oxygen and other byproducts.

CE 2.6

Algae Habitat

I have found that the algae are the most robust organisms available in the earth. The main reason for the higher number of species is that it can survive under any natural circumstances. However, I have found that the most favorable birthplace for the algae is the wet and damp place. It has been found that the terrestrial and the tropical algae are not that much effective for the production of the biodiesel than the algae produced in the wet and damp place. The other thing what I have found while working with this project is algae can grow in any part of the world starting from the deepest point of the sea to the driest land on the earth.

CE 2.7

Composition of Algae

I found that the most of the algae are made of the eukaryotic cells. The differential features of this cell are that it is organelles but contain the nuclei. The composition of the algae differs from the composition of the proteins, carbohydrates and the different types of chlorophyll. I have learnt that the some of the algae can only have chlorophyll. The following table will illustrate the composition of the different kind of algae strains.

|

Strain |

Protein |

Carbohydrates |

Lipids |

Nucleic acid |

|

Scenedesmus quadricauda |

47 |

- |

1.9 |

- |

|

Scenedesmus obliquus |

50-56 |

10-17 |

12-14 |

3-6 |

|

Chlamydomonas rheinhardii |

48 |

17 |

21 |

- |

|

Scenedesmus dimorphus |

8-18 |

21-52 |

16-40 |

- |

|

Chlorella vulgaris |

51-58 |

12-17 |

14-22 |

4-5 |

|

Spirogyra sp. |

6-20 |

33-54 |

11-21 |

- |

|

Chlorella pyrenoidosa |

57 |

26 |

2 |

- |

|

Dunaliella bioculata |

49 |

4 |

8 |

- |

|

Euglena gracilis |

39-61 |

14-18 |

14-20 |

- |

|

Dunaliella salina |

57 |

32 |

6 |

- |

|

Prymnesium parvum |

28-45 |

25-33 |

22-18 |

1-2 |

|

Porphyridium cruentum |

28-39 |

40-57 |

9-14 |

- |

|

Tetraselmis maculata |

52 |

15 |

3 |

- |

|

Spirulina platensis |

46-63 |

8-14 |

4-9 |

2-5 |

|

Synechoccus sp. |

63 |

15 |

11 |

5 |

|

Spirulina maxima |

60-71 |

13-16 |

6-7 |

3-4.5 |

|

Anabaena cylindrica |

43-56 |

25-30 |

4-7 |

- |

CE 2.8

The main reason for selecting the Algae (Microalgae)

Before the staring of the project, I have looked after about the other resources for the development of the biodiesel. However, through considering four aspects I found that the algae are the best source for the development of the biodiesel. The key four aspects that I have taken under consideration are:

- Climate change factor

- Security of the energy

- Synergy between the algae and the coal

- Aquatic biomass v/s the terrestrial biomass

Carbon dioxide is believed to be the most harmful pollutant for the natural environment. I found that the emergence of the “green house effect” has increased the environmental pollution. Due to these environmental conditions, the algae will be the most attractive resource for the biodiesel. Moreover, the algae development will reduce the effect of the carbon dioxide.

The energy security is a very large concern for the current world. The coal and the petroleum are going to be a scary resource for the energy sector in coming day. Therefore, the energy production through the algae is going to be the best option. The other reason for the selection of the algae is that it produces rich quality oil that have a good commercial prospect.

The energy production through the coal and the fossils emits carbon dioxide. However, the algae have the ability to offset the harmful effect of the emitted carbon dioxide. I have seen that the most of the algae develops in the aquatic environment. The most of the industries have acquired the available land. Therefore, if the energy development through the algae is possible then it will create a synergy between the aquatic biomass and the terrestrial biomass.

CE 2.8

Algae production system

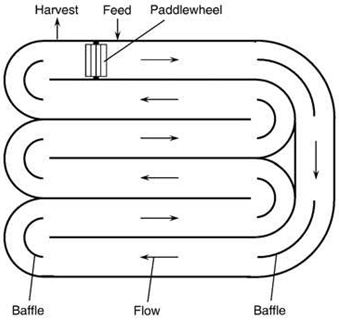

I have found that the algae can be a good prospect for the agricultural activity. On the production, I have found that the biomass can be produced through two ways. One is the open system through the race away ponds and the other one is through the closed systems. In closed system the biomass production is done through the photo bioreactors. The structure of the race away pond generally follows the following structure.

In the closed system, it needs to be use different types of photo bioreactors. The most commonly used reactors I found are the flat plate photo bioreactors, tabular photo bioreactors, vertical column photo bioreactors and internally illuminated photo bioreactors.

Summary

CE 2.9

Throughout this project I have learnt that the biodiesel has a wider scope of commercial success. Moreover, it the main bright aspect is that the most of the developed and the developing nations are considering this fuel as a boost to the economy. The other thing what I have learnt is that algae is the safest and the most sustainable resource for the development of the biodiesel because of it sustainability in the different climatic conditions.

Career Episode 3

CE 3.1

This career episode 3 demonstrates my understanding about the hydrodynamics through the project “A study of hydrodynamics in Bubble column reactors”. I have done this project through sole responsibility. I have completed this project as a part of my academic requirement. I have conducted this project in my college, which is STES’S Sinhgad College of Engineering. This college is affiliated under the Pune University.

Chronology:April 2008

Physical Location:Pune, India

Name of the Organization: Sinhgad College of Engineering, Sinhgad Technical Education Society

Position held: Student

Name of the Project: A study of Hydrodynamics in bubble column reactors

Background

CE 3.2

The main concept of the bubble column is that in this column the discontinuous gas phase bubble gradually becomes continuous. The bubble column is the general multiphase reactors. It contains three main categories one is the trickle bed reactor this can be fixed or packed bed, the other one is the fluidized bed reactor and the third one is the bubble column reactor.

CE 3.3

Application of the Bubble Column Reactor

I have found that the application of the bubble column reactor in many areas. However, the most important areas where I have found the bubble column reactor has used very widely are:

- In the production of the synthetic fuel through the conversion of gas

- In the biochemical process

- Coal liquefaction process through the Fischer Tropsch process

- Environment friendly synthetic oil production system usages this kind of reactors

- In the synthesis of the methanol

- Air oxidation and oxidation of the inorganic compounds

- In industry, the most commonly used bubble columns is the vertically sparged bubble column reactors. In industry, it is used for the chemical process like the Fischer tropsch synthesis, liquefaction of the coal etc.

CE 3.4

The advantage of using the bubble column reactor

The main advantages what I have found in using the bubble column reactor are :

- Lesser complexity due to the absence of the moving parts

- Lesser effort in the maintenance

- Higher heat transfer rate is possible through this reactor

- The installation cost is much lower than the other reactors. The main reason behind this is that it occupies lesser amount of space.

- Higher durability

- The pace of the reaction can be controlled very easily in this reactor.

These are the main advantages what I have found while looked for the popularity of this reactor in the industry sector.

CE 3.5

The major disadvantage of the bubble column reactor

The major disadvantage what I have found in using these kinds of reactor are the chances of higher-pressure drop and the coalescence.

CE 3.6

The main characteristic of the Bubble column reactor

The main characteristics of the bubble column reactor are:

Flow Regimes, it is the heterogeneous flow regime. This flow is achieved at the low superficial gas velocities. The velocity of the gas remains lesser than the 5 cmfs in the semi batched columns. The other characteristic of the bubble column reactors is the gas hold up. The gas hold up defines the volume fraction of the gas phase that is occupied by the gas bubbles. While working in this project I have found that the gas holdup plays a very important role in the bubble column reactor.

CE 3.7

Mass Transfer and the Heat Transfer

The mass transfer refers to the liquid side mass transfer. The entire transfer rate is controlled and maintained by the liquid side mass transfer coefficient. I found that the difference in the coefficient generally occurs due to the variations in the interfacial area. I found that most of the journals and the books highly concentrate in the estimation of the mass transfer coefficient.

The heat transfer coefficient is related with the endothermic heat supply and the exothermic heat operation. In this content I found that the most important part is the transfer of heat from the walls of the reactor and the inside coils that is directly connected with the liquid. I have found that the heat transfer rate in the case of the gas-liquid bubble column has been recorded approximately 100 times higher than the single phased flow.

Summary

CE 3.8

This project has enabled me to understand the various aspects of the bubble column reactors. Through the study, I also found the important relationship between the various coefficients of the bubble column reactors. Throughout this study, I have understood the main reasons for the use of the bubble column reactor in the most of the industrial sector. However, I also found that the some sort of limitations of the usage of the bubble column reactor in the industry sector. Though it has been seen that if the instrument is used in the controlled manner it can provide much better result than the other reactors.

Our Exclusive Features

A Direct Network For Student & Experts

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

A Direct Network For Student & Experts

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

A Direct Network For Student & Experts

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

A Direct Network For Student & Experts

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

394 Order Completed

394 Order Completed 302 Reviews

302 Reviews